vinto wide

Decors

Matching Accesories

Eco Wood

Expert Heat Aquastop

Pro Natur

Extra Aquastop Smart

Maxima Aquastop Smart

XPS Easy

XPS Extra

XPS Light Flex

PE film

Aluminium self-adhesive tape

XPS Maxima

Skirting board K40C

Installation clip

Universal plastic pipe collar

Clickguard™ joint sealant

Tapping wood

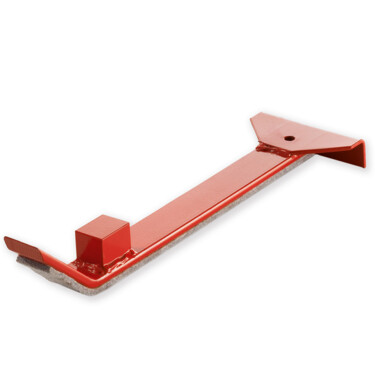

Pull iron, wide

Spacer, hard wood

Spacer, plastic

Laying set

Acrylic sealant

Laminate cleaner

Stain remover

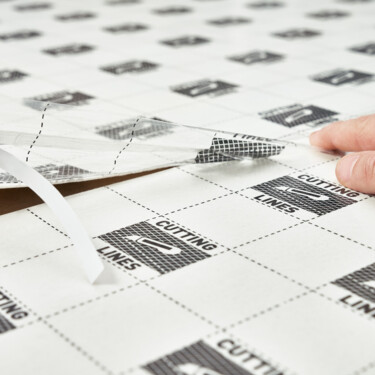

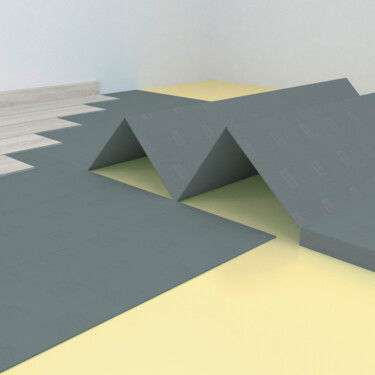

Laying

The tried-and-tested LOGOCLIC® click system makes laying the elegant laminate child’s play. You can find more detailed information on the 1clic2go Pure system on our information pages on laying laminate flooring.

Find the installation guide for 1clic 2go pure and 1clic 2go pure+ for download.

| Core material | HDF |

|---|---|

| Certification | PEFC |

| Usage class | Usage class 23/32: for high-use residential areas/for moderate-use commercial areas |

| Suitable for | Hot water underfloor heating |

| Mechanical protection | Pressure-resistant, impact-resistant, scratch-resistant |

| Slip resistance | DS |

| Abrasion class | AC4 |

| Chair castors suitable for | Private use |

| Fire behaviour | Cfl-S1 |

| Environment/health | Low-emission, solvent-free, free of softening agents |

| Product note | Decors are wood imitations |

| LOGOCLIC® warranty | 20 years |

What exactly is laminate?

Laminate is a very popular floor covering nowadays, which is often used as an alternative to real wood flooring due to its advantageous properties such as abrasion resistance, durability, robustness, easy maintenance and much more. The large selection of surface decors allows for many different furnishing styles.

What is the best way to clean and care for my LOGOCLIC® laminate flooring?

Laminate from LOGOCLIC® is extremely easy to maintain, smooth and sturdy. It is difficult for dirt to stick. For this reason, it is sufficient to vacuum or wipe down with a damp cloth. Fine dust can be removed in no time. This makes simple and straightforward cleaning of the laminate flooring possible. Nevertheless, you should heed a few basic rules to ensure long years of enjoyment of your laminate flooring.

- Before cleaning, the floor should be vacuumed or swept to remove coarse dust and dirt.

- In the next step, the laminate floor is mopped. Here, the rule is: use as little water as possible. Experts call this damp cleaning – only just damp, as if the floor has been wet by a light mist. If too much water is used, the water can collect in the joints, leading to swelling of the coreboard.

- If you like, you can wipe the floor down with a dry cloth afterwards – preventing streaking.

- You can also add LOGOCLIC® laminate cleaner to the cleaning water. This contains additional care substances which serve to maintain the optimum appearance of the laminate floor.

What do I do if I have scratches or surface marks in the laminate?

Although laminate flooring from LOGOCLIC® is resistant to impact, scratches and abrasion, scratches can still appear in the laminate flooring over time. But that is no reason to remove the whole floor straight away! You can quickly and easily repair individual scratches – and the laminate floor will look like new again.

During installation, the hammer fell on the floor and now a piece of the surface has chipped off. What can we do without replacing the entire floor?

Laminate flooring from LOGOCLIC® is resistant to impact, scratches and abrasion and is very robust. But it is not a miracle floor and so even this flooring can show scratches or dents over time. Yet laminate is very easy to care for – and that includes repairs.

What is the surface of laminate panels made of?

The advantage of laminate flooring compared with real wood is that the floor covering is made of many different layers and is thus extremely sturdy and resistant to impact, scratches and abrasion.

Some LOGOCLIC® laminate product lines, for example the Silentos or Ambienta series, have integrated footfall and impact sound insulation. This forms the bottom layer in the structure of a laminate panel. Above this is the stabilising layer, which balances the tension from the top to the bottom surface. Above the stabilising layer is the HDF core material, a stable wood-based panel. LOGOCLIC® has an antistatic paper on top of this, which prevents unpleasant discharge.

The last two layers make the laminate what it really is: a beautiful floor covering with its advantageous properties and beautiful appearance. Above the anti-static paper is the decorative layer with the decor for the respective floor. This layer is impregnated with a melamine resin. Together with the overlay, the top layer of the laminate flooring, the decorative layer is pressed firmly onto the core material under heat and pressure.

What is the difference between laminate and parquet?

There is a major difference in composition between parquet and laminate. The surface of parquet is made of real wood, while a decorative surface in wood or stone look is used for laminate.

Laminate from LOGOCLIC® is made of around 90 percent wood-based materials from domestic wood. The five or six layers (overlay, decorative layer, antistatic paper, HDF core material, stabilising layer, footfall and impact sound insulation) of the laminate structure make the flooring robust, easy to maintain, antistatic and resistant to impact, scratches and abrasion. These properties distinguish the floor covering from parquet flooring, which requires much more intensive maintenance.

Is laminate a suitable flooring for allergy sufferers?

The decision in favour of laminate flooring from LOGOCLIC® is also always a decision for your health. And for good reason: unlike in the dense carpet fabric, dust and dirt do not find a foothold on the smooth surface of laminate flooring and dust mites therefore have no habitat. Thanks to the closed surface, LOGOCLIC® laminate does not offer allergy-causing micro-organisms a basis for feeding or breeding.

Since laminate is mainly made of wood, is it also easily flammable?

Laminate from LOGOCLIC® consists of more than 90 percent wood-based materials from domestic forests. So is it right to assume that laminate is highly flammable because wood also burns easily? The opposite is the case: laminate floors from LOGOCLIC® are classified as flame retardant.

According to DIN (German Institute for Standardisation) 4075 Part 5, laminate from LOGOCLIC® is flame retardant. The classification according to the European standard is: DIN EN13501-1 – Fire class CflS1 (Cfl – flame retardant; S1 – no smoke development).

What is impact sound and footfall sound and what can I do about it?

Impact sound is generated by walking on the floor and is transmitted via adjacent walls and the subfloor/ceiling into adjacent rooms – for example into those of the subtenant – and emitted as airborne sound.

Impact sound is generated by walking on the floor and is transmitted via adjacent walls and the subfloor/ceiling into adjacent rooms – for example into those of the subtenant – and emitted as airborne sound.

Laminate floor coverings are very hard. In addition, laminate flooring is seldom glued down, it is usually laid as a floating floor. This causes the noise when the floor is walked on. However, with the right footfall and walking sound insulation, the noise can be reduced to a minimum. This is laid under the laminate before the laminate is laid. At LOGOCLIC® you will find different types of footfall and impact sound insulation.

The Ambienta product lines already have integrated footfall and impact sound insulation. The unique Silentos Pro system from LOGOCLIC® consists of a PO foam layer 2.0 mm thick that reduces room sound by up to 50 percent and impact sound by up to 30 percent.